Pipe & Joint System

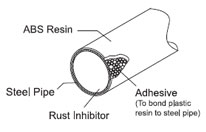

These units convey containers or bins to workstations, assembly points, machine loading posts, kitting locations and other stations of usage. System consists of plastic-coated steel pipe sections that are cut to required plan lengths and metal joints that tighten onto pipe sections via a threaded fasteners. Pipe comprises of plastic layer, binding layer, steel tube layer and spray-paint layer. The outer layer is made of PE, PVC or ABS; the intermediate layer is steel tube and the inner layer is coated antirust paint to have better resistance against corrosion and rusting. The adhesive layer between the plastic layer and steel tube layer binds these two layers in a seamless connection through special adhesive. Steel tube ends are sealed to connection fittings that are specially designed. Various joining are used to connect all fittings and the installation is very easy. Both ends are sealed with rubber plugs to isolate air and moisture so that the steel tube is not subject to rusting. Units may be built with stabilizing feet, including height adjustable styles, or with casters to make the units easily maneuverable for easy housekeeping, or for transport to other areas. Casters with brakes hold stands securely in place during use. If part needs change or operations are modified, the use of metal joints allows stands to be disassembled and reconfigured using most of the existing components. Ease of design and construction allows users to custom match their own specific-style part presentation stands to individual application needs.

|

|||||